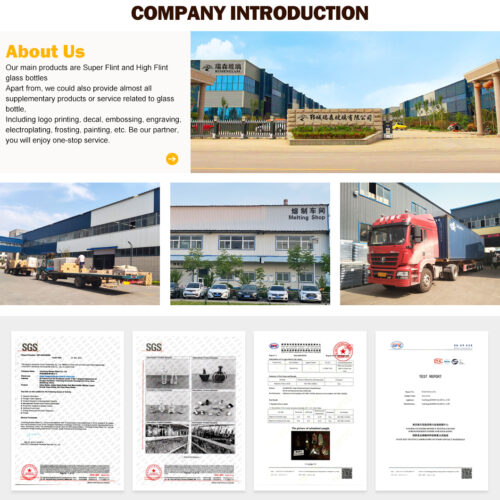

Bottle Manufacture

Our main products are Super Flint and High Flint glass bottles

Apart from, we could also provide almost all supplementary products or service related to glass bottle,

Including logo printing, decal, embossing, engraving, electroplating, frosting, painting, etc. Be our partner, you will enjoy one-stop service.

Your Glass Bottle Ideas

We start the design from a sketch, or better yet, use a sample of a glass bottle against the design (similar bottle, send us a bottle sample), or we can discuss your ideas first.Derive the final solution for bottle manufacture

The design team will continue to understand your brand story, make a sketch that fits your idea, consider your cost, and improve the program to make the project progress smoothly.

2. Making glass bottle molds

Molds are the key to glass bottle molding, providing a complete set of mold details to strictly match the shape of the bottle you need.

Including initial mold, molding mold, bottle mouth mold, bottle bottom mold to meet the one-stop service of bottle manufacture

3.Raw materials of glass bottles

The raw materials used to make glass bottles are sand, soda ash, limestone and broken glass, of which broken glass is infinitely recyclable, also indicating that glass is a very environmentally friendly material and is the only packaging material that is 100% and infinitely recyclable.

4. Melting of glass material

The raw material is subjected to an intense fire at about 1550°C in a heating furnace. The water vapor evaporates, the trash is burned off and the raw material forms a glassy liquid. Finally, the glass liquid is cut into weight-like droplets and put into the mould.

Our furnaces are fully automated and are controlled by our engineers from the control room using software.

5. Formed Glass Bottles

Using a metal chute, drops are put into the initial mold to form an initial bottle shape (mouth and bottom), which is then placed into the finished mold by a robot and blown into its final shape with the help of compressed air

Combination of fully automatic machine and semi-automatic machine, we will choose the right unit according to your design to ensure the recent quality of the product

6. Blown Glass Forming Process

After the drops enter the mold, compressed air is used to shape the bottle.

This process is suitable for the production of spirits bottles, wine bottles, beverage bottles, see our catalog