Because the quality of glass bottles is directly related to the safety and quality of products, how to judge whether a glass bottle manufacturer is qualified is of great significance to enterprises. The following is from the manufacturer’s quality management system, production equipment, product quality, after-sales service, and other aspects, summarizing several key factors to judge whether a glass bottle manufacturer is qualified.

- Quality management system

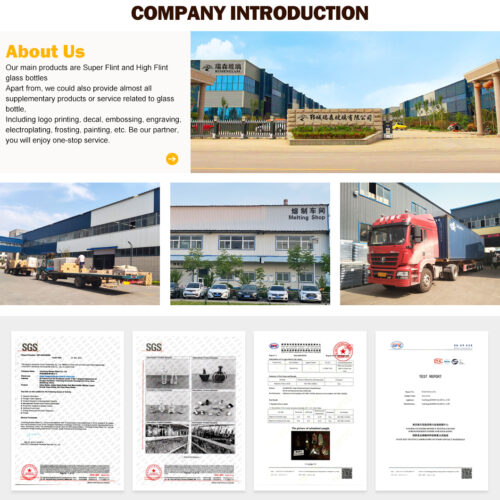

A qualified glass bottle manufacturer must establish a sound quality management system and pass the ISO9001 quality management system certification. This means that the manufacturer has a standardized quality management process and effective quality monitoring and improvement mechanism to ensure that the production of glass bottles meets the standards and customer requirements. In addition, the manufacturer should also organize regular internal training to improve the cognition and level of employees on quality management and further ensure the quality and stability of products.

- Production equipment

Production equipment is one of the important factors affecting product quality. A qualified glass bottle manufacturer must have advanced production equipment and technology and constantly update and upgrade equipment to meet customer needs and market changes. Meanwhile, Yuncheng Ruisen Glass Co., Ltd. should also pay attention to the maintenance and regular inspection and repair of equipment to ensure that the equipment is in good condition and ensure the stability and consistency of the product.

Third, product quality

Product quality is the key factor to judge whether a glass bottle manufacturer is qualified. A quality glass bottle should have the following characteristics:

- The appearance is smooth and clean. The surface of the glass bottle should be flat and smooth, free of bubbles, defects and foreign bodies. At the same time, the bottle mouth should be smooth and regular, and the lid can be closely chimeric, not easy to leak.

- Even thickness. The thickness of the glass bottle should be uniform, without excessive weak points, able to withstand certain pressure and temperature changes, and not easily damaged or deformed.

- Good transparency. Quality glass bottles should have good transparency and clearly show the color and texture of the product so that consumers have a clearer understanding of the product.

- Strong drug resistance. Resistance in glass bottles is a very important indicator for industries such as pharmaceuticals and cosmetics. Glass bottles should be fully compatible with various pharmaceutical products without adverse effects on the product.

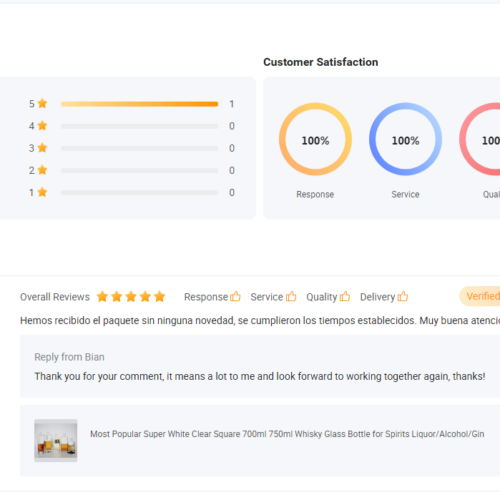

Four, after-sales service

A qualified glass bottle manufacturer should provide good after-sales service while ensuring product quality. This includes providing technical support and guidance in using products, timely solving problems encountered by customers in using products, etc. At the same time, manufacturers should also establish a perfect after-sales service system to ensure that they can timely and effectively deal with customer feedback and complaints, improving customer satisfaction and trust.

To sum up, judging whether a glass bottle manufacturer is qualified needs to start from many aspects, including quality management system, production equipment, product quality, after-sales service, and so on. When choosing glass bottle suppliers from Canada or any other part of the world, enterprises should choose a qualified manufacturer with appropriate qualifications, advanced equipment, reliable quality, and thoughtful service according to their own needs and requirements so as to ensure the safety and quality of products and create a more high-quality and healthy consumption environment.