Introduction

Quality of Packaging plays a significant role in the presentation of products. It is the symbol of a brand’s identity, a silent ambassador that communicates values and a commitment to quality that never wavers. The choice between glass versus plastic bottles holds significant weight, especially when it comes to preserving freshness and maintaining aesthetic appeal.

There are various advantages and properties associated with glass and plastic packaging. That adheres to the specific needs and preferences of diverse industries and consumers. However, it’s important to consider the raw materials, sustainability, and health & safety concerns. Read on to learn about the properties of Glass bottles vs plastic bottles, their benefits, environmental impact, and more.

Glass packaging is often seen as a sign of high-quality premium products. Its transparent nature allows consumers to see the product clearly, which enhances the perceived value and brand image.

There’s a huge demand for single-use plastic packaging products on the market. It is often seen as a convenient and inexpensive way to package everyday items. This is evident in the fact that 47% of retail packaging sales come from plastic and PET bottles.

Does this make plastic a superior material? Let’s take a closer look.

Related Article: Swing Top Glass Bottles: Comprehensive Analysis

Glass Packaging

For over a century, glass carved its niche in the beverage packaging industry. Thanks to its timeless appeal and inherent qualities. In the United States alone, the glass container industry boasts a remarkable $5.5 billion value. This vibrant sector is further supported by a vast network of over 80 recycled glass processors operating across 30+ states.

Beneficial environmental impacts

While glass bottles offer many benefits, they do have some significant environmental impacts, as follows:

1. Glass is inert and does not leach chemicals into the liquor, which is crucial for preserving the original taste and quality of the beverages.

2. Glass offers superior barrier properties. These unique properties protect the liquor from harmful light, oxygen, moisture, and microorganisms.

3. Glass has a high recycling rate of 76%, making it an environmentally friendly solution.

4. The smooth surface of glass bottles makes them easy to clean, and their ability to be reused cuts down on waste.

5. Glass bottles ensure longer product shelf life.

That’s why most liquor manufacturers prefer glass packaging for their premium products. For instance

1. Glass wine bottles

2. Glass liquor bottles

3. Glass perfume bottles

And more.

Do you require complex glass bottle packaging? In that case, custom glass bottle manufacturers are the best choice. Here’s how the process works.

Glass bottle manufacturing process

It takes heat, pressure, and precise control to transform raw materials into elegant and practical glass bottles. Although the process appears straightforward, it involves several intricate steps and a lot of hard work.

Raw Material Preparation: The production of glass bottles requires the use of natural and specific components. The workers prepare and melt down these components to form the desired shape of the glass bottle. The beverage, pharmaceutical, and cosmetics industries use similar raw materials to make bottles for their various products.

Here are the primary raw materials utilized in glass bottle production.

●Silica sand:

It acts as the main source of silicon in the glass composition. Also provides the necessary chemical properties to form a stable structure.

Other materials,

●Soda ash (Sodium Carbonate)

●Limestone (Calcium Carbonate)

●Cullet (Recycled Glass)

These ingredients modify the properties of glass and improve its manufacturing process.

Melting: In this phase, manufacturers mix and feed raw materials into a furnace. Where intense heat of approximately 1500°C melts them into a viscous liquid known as a “glass batch.”

Forming: Workers use the Blow Molding technique. They transfer a precise amount of molten glass into a pre-shaped mold. Afterward, Compressed air is then blown into the gob. The air forces the molten glass into the desired shape, and it takes the shape of the mold. You might also be interested in learning how the complex and difficult shapes of glass bottles are formed.

For more complex shapes and patterns, the press-and-blow method comes into play. This technique combines the use of a pressing mold to form the initial shape, followed by blowing to achieve the final desired form.

At last, bottles undergo a thorough inspection process. Final inspection ensures they are free of defects, such as Scratches, bubbles, or inconsistencies in shape and size.

Plastic Packaging

Plastic packaging is a versatile and popular choice. A range of benefits align with the demands of modern manufacturers and consumers. Plastic is a popular material for food and beverage containers, product packaging, and more. That offers a lightweight, durable, and economical alternative to glass. However, the convenience of plastic packaging comes at a significant environmental cost. As the beverage industry grows, plastic is becoming more and more prevalent.

Plastic packaging consists of:

1. Plastic bottle

2. PET (Disposable bottles)

3. HDPE bottle

4. LDPE bottle

5. Food-grade plastic bottles

Benefits

1. Plastic bottles are lightweight and easy to handle, making them ideal for on-the-go consumption.

2. Plastic is highly resistant to breakage. That makes plastic bottles suitable for transportation and less susceptible to damage.

3. Usually, PET Plastic packaging is cheaper to produce than glass. As a result, it becomes more affordable for manufacturers and consumers.

4. Plastic’s malleability lets companies mold it into any shape and size. Resulting in innovative and diverse product packaging that reflects distinct brand personalities.

Plastic bottle manufacturing process

The plastic bottle manufacturing process is cheaper and requires less effort. It’s important to remember that the recycling rate of plastic is low when compared to glass bottles.

Preparation of Pellets: The process begins with petrochemicals derived from fossil fuels. These undergo complex chemical reactions to form polymers, the building blocks of plastic. Next, the workers melt the polymers and extrude them into small cylindrical pellets. The pellets are ready for further processing into plastic products.

Blow Molding: In this next phase, plastic pellets become the key ingredient. Workers feed them into a hopper, where intense heat melts them into a molten state. After that, they inject this molten plastic into a pre-shaped mold. Where compressed air inflates it, forcing it to conform to the desired bottle shape.”

Cooling Process: Wait for a moment until the plastic becomes cool and firm within the mold. The workers immediately eject the newly formed bottle and transport it to the next stage. The bottles then undergo various finishing processes, depending on their intended use.

Glass bottles vs plastic bottles

Health and Safety concerns

Polymers are the primary ingredients that create our plastic bottles. Most of them contain harmful substances, like bisphenol A (BPA) and Styrene. If exposed to sunlight or heated in a microwave, these chemicals can leach into the container. This can cause contamination of the food or drink it contains. It is important to be aware of this and use appropriate containers for storing food.

Americans consume more than 50 billion (disposable) plastic water bottles each year. Plastic does not degrade as quickly as organic materials. When plastic is disposed of in landfills and oceans, it pollutes the environment and harms marine life. This resulted in a global discussion about safe and responsible plastic use.

Glass bottles retain nothing of the previous contents. Each use of a glass bottle will be free of residual scents. This quality is beneficial to maintain the true nature of the product in glass bottles.

Cost-effectiveness

The upfront cost of producing glass bottles is higher than that of plastic bottles. Glass bottles need more energy and resources to manufacture. This increases production costs, shipping costs, and labor costs. In contrast, the production of plastic bottles is cheaper. It is because the raw materials and manufacturing process are less expensive.

However, it’s also important to consider the long-term costs for each type of material. Glass bottles are more durable and can be reused multiple times, which can offset the higher initial cost. Plastic bottles are generally not as durable and can degrade over time, requiring more frequent replacement.

Practical applications

Glass bottles

●Glass bottles are the preferred choice for wines, beers, and other high-value beverages.

●Its unique nature preserves its original aroma and quality.

●Glass provides excellent chemical resistance. Glass bottles are ideal materials for packaging sensitive medications and cosmetics.

Plastic bottles

●Plastic packaging is ideal for on-the-go consumption because they are convenient and affordable.

●Bottles of plastic are the primary packaging for water, soda, juices, and energy drinks.

.

●Plastic bottles come in a wide range of shapes and sizes. You can get single-serve bottles to large family-sized containers,

Indeed, plastic offers several advantages, like affordability, versatility, and durability. In most cases, its disadvantages outweigh the benefits in terms of its environmental and human health impact.

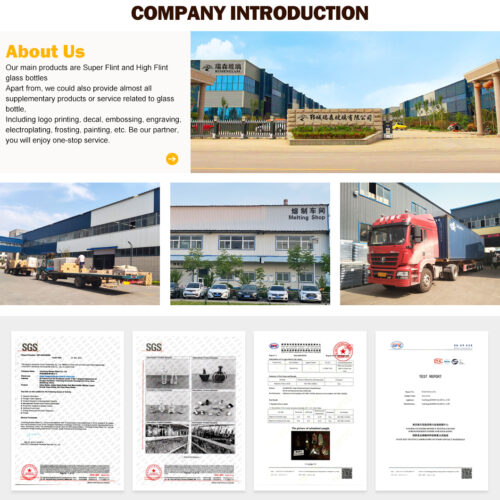

Ruisen glass bottle manufacturer

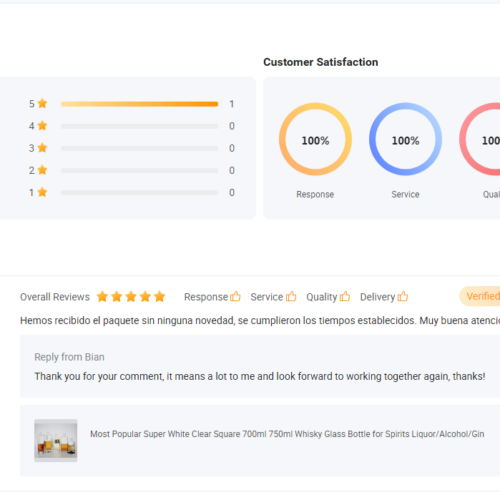

Ruisen Glass stands out as the best glass bottle manufacturer that provides top-notch products. Aside from our extensive product selection, we also offer extensive customization options. As a top-of-the-line glass bottle supplier, we prioritize quality and promise excellent customer service. We produce a variety of custom glass packaging of the highest quality. Ruisen Glass specializes in supplying diverse packaging products tailored to each client’s requirements. As a leading manufacturer, we have extensive experience and advanced production equipment. Here’s what we offer

●Custom glass bottle packaging (ranging from 50ml – 3000ml)

●Glass Perfume Bottles

●Glass Wine Bottles

●And liquor bottles

Also, we offer bottles of vodka, whiskey, and others within the shortest lead times. Ruisen Glass is committed to customer satisfaction and strives to create innovative solutions.

Conclusion

Choosing between glass and plastic bottle packaging is more than just selecting materials. It affects sustainability, aesthetics, and, most importantly, consumer experience. You’ll find information on manufacturing processes and health & safety aspects to make an informed decision. In case you wish to consider a sustainable option, we recommend Glass bottles.

According to research, a staggering US$100 billion in plastic packaging material disappears each year due to reliance on single-use plastic packaging. Unfortunately, this linear process returns only 2% of waste for recycling. Which emphasizes the urgent need for change. Analyze the advantages and disadvantages of each choice before making a decision.